PRODUCTS CENTER

ProduCTS center

It has rich technical experience in the fields of non-ferrous wire, stranded wire, calendering and rolling, and is an innovative and high-tech enterprise in Sichuan Province.

15t rectangular regenerative aluminum melting furnace

Keywords:

Category:

Product description

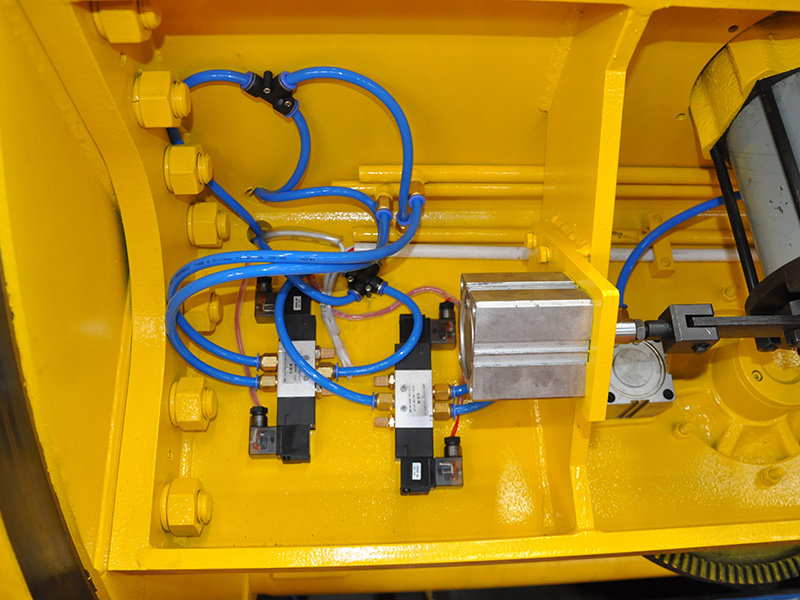

Rolling mill is the equipment to realize the metal rolling process, which generally refers to the equipment to complete the whole process of rolling production. Rolling mills can be divided into two, four, six, eight, twelve, eighteen, etc. according to the number of rollers; According to the arrangement of rollers, it can be divided into "L" type, "T" type, "F" type, "Z" type and "S" type. Ordinary rolling mill is mainly composed of roller, frame, roll pitch adjustment device, roll temperature adjustment device, transmission device, lubrication system, control system and roll removal device. In addition to the main parts and devices of ordinary rolling mills, the precision calender adds a device to ensure calendering accuracy. It is named according to the rolling variety, rolling mill type and nominal size. The principle of "nominal size" for profile rolling mills is named after the herringbone gear pitch diameter of the gear seat; The primary rolling mill is named after the nominal diameter of the roll; Strip mills are named after the length of the working roll body; Tube rolling mills are named after the largest pipe diameters produced. It is also sometimes named after the inventor of the rolling mill.

HOT PRODUCTS

ONLINE MESSAGE