PRODUCTS CENTER

ProduCTS center

It has rich technical experience in the fields of non-ferrous wire, stranded wire, calendering and rolling, and is an innovative and high-tech enterprise in Sichuan Province.

Axis

Keywords:

Category:

Product description

JLK630Z/12+18+24 frame stranding unit

(overall side horizontal upper and lower disc units).

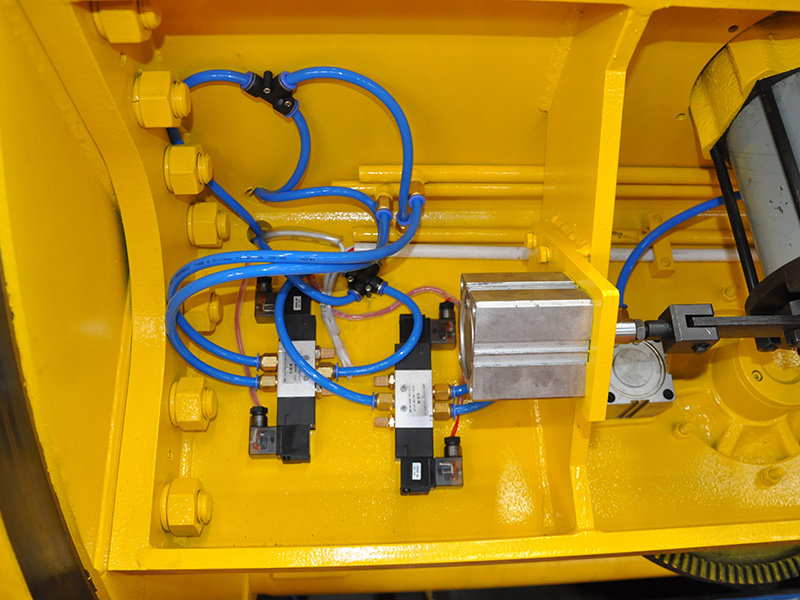

Equipment use and characteristics

1.1 The main power supply line cable factory of this machine twists large-section aluminum stranded wire, steel core aluminum stranded wire, copper stranded wire and stranded wire of insulated wire. It is suitable for the production of large length bare aluminum and bare copper wire twisting and pressing.

1.2 This machine has an overall upper coil device, high degree of mechanization, complete auxiliary functions, large reel capacity, high production efficiency, and is an ideal equipment for the production of various non-detwisted wires.

1.3 The wire reel of the unit is divided into four equal parts around the twisting cage, which is convenient for the overall upper and lower reels, high rigid strength of the equipment, good overall performance, small moment of inertia and high running speed.

1.4 The machine adopts 36-level traction gear gearbox, double active and double traction device, and the equipment pay-off tension adopts air tension control to ensure that the tension is uniform when the wire reel is full and empty. The noise is not more than 85 dB.

1.5 Fully disconnected automatic parking device with unique function, disconnection parking is directly controlled to each pay-off reel, when the disconnection reel stops, the host immediately automatically stops.

Main technical parameters

|

model |

single wire diameter (mm). |

stranded diameter (mm). |

the twisting speed (rpm). |

stranded pitch (mm). |

|

JLK630/6+12+18+24 |

Copper1.5~4.5; Al 1.8~5 |

45 |

207~54 |

38~1104 |

|

JLK630/12+18+24 |

45 |

176~54 |

45~1104 |

|

|

JLK630Z/6+12+18 |

Copper 1.5~4.5; Al1.8~5 |

35 |

207~64 |

38~930 |

|

JLK630Z/6+12+18+24 |

45 |

207~54 |

38~1104 |

|

|

JLK630Z/6+12+18+24+30 |

55 |

207~45 |

38~1324 |

|

|

JLK630Z/12+18+24 |

45 |

176~54 |

45~1104 |

|

|

JLK630Z/12+18+24+30 |

55 |

176~45 |

45~1324 |

3. Main components of equipment

|

1 |

PN1600 shaftless pay-off device |

1 sets |

6 |

meter meter |

1 sets |

|

2 |

12, 18, 24 coil stranding bodies |

each (3 sets in total). |

7 |

Parallel die bases and compression frames |

3 sets |

|

3 |

12, 18, and 24 discs are housed horizontally |

each (3 sets in total). |

8 |

main gearbox and 36-stage transmission gearbox |

1 sets |

|

4 |

φ2500 traction device (dual active). |

1 sets |

9 |

electric control box and operation console |

1 sets |

|

5 |

φ2500 end-shaft wind-up device |

1 sets |

10 |

shield |

3 sets |

HOT PRODUCTS

ONLINE MESSAGE