PRODUCTS CENTER

ProduCTS center

It has rich technical experience in the fields of non-ferrous wire, stranded wire, calendering and rolling, and is an innovative and high-tech enterprise in Sichuan Province.

Copper wire drawing machine high speed

Keywords:

Product description

LHD450/13 copper wire pull unit

(13-mold continuous annealing high-speed copper large pull unit).

1. Unit use and performance characteristics

The unit is used to draw the copper rod into a single copper wire.

After the copper rod is drawn by the pay-off frame into the wire pulling machine, the line coming out of the fixed speed wheel is directly annealed and softened, and finally the wire is closed by the double-disc take-up machine or the loop take-up machine.

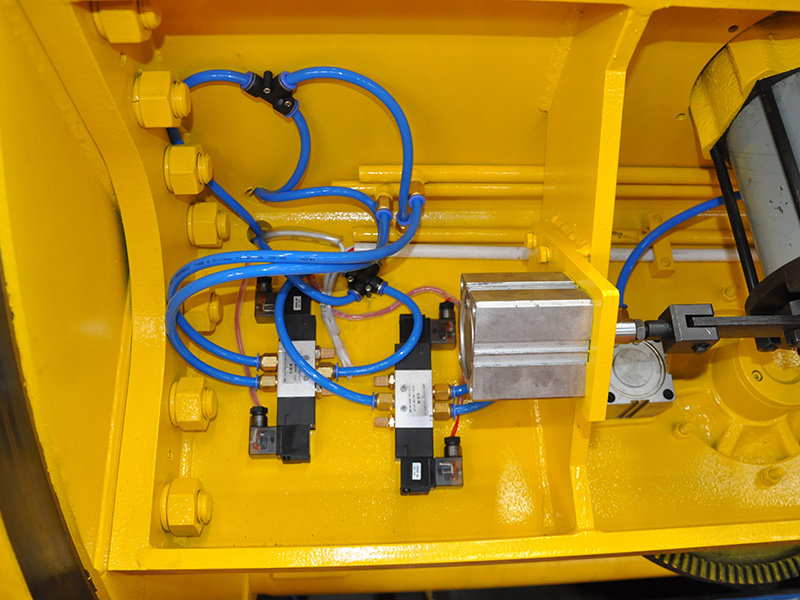

The machine absorbs foreign advanced technology, adopts in-line sliding continuous pulling wire, and the drum is immersed in the wire emulsion to draw copper wire, and the main gearbox, wire pulling and annealing device are equipped with a set of lubrication and cooling circulation system.

The machine group is fully mechatronic, using PLC programming, touch screen full-thread control, mechanical and electrical speed balanced matching, to achieve fast mold change, full pneumatic automatic non-stop changing of the wire and winding. The production process is displayed on the color touch screen man-machine interface, and the man-machine dialogue is used to query, adjust and control. It has the advantages of convenient operation, high production efficiency and good product quality.

2. Technical parameters

|

model |

drawing passes |

the wire entry diameter |

the outlet diameter |

the maximum exit speed |

technical features |

|

LHD450/9T |

9 |

8 |

2.1~4.0 |

20 |

drawn copper wire |

|

LHD450/11T |

11 |

8 |

1.7~4.5 |

22 |

|

|

LHD450/13T |

13 |

8 |

1.2~4.5 |

25 |

3. Unit composition:

Spiral arm double station pay-off frame - wire drawing host - wire cooling lubrication system - storage line tension control device - annealing device - annealing cooling lubrication system - steam generator - pneumatic double disc automatic take-up device - - Coil-forming take-up machine - PLC electrical control system - rolling head mold threading machine.

HOT PRODUCTS

ONLINE MESSAGE