PRODUCTS CENTER

ProduCTS center

It has rich technical experience in the fields of non-ferrous wire, stranded wire, calendering and rolling, and is an innovative and high-tech enterprise in Sichuan Province.

Aluminum alloy aluminum non-slip wire drawing machine

Keywords:

Product description

LFD450/13 non-sliding aluminum alloy wire pull unit

(13-mode non-sliding aluminum alloy compatible with Pu aluminum high-speed large-pull unit).

Technical specification

Features

It is used to draw aluminum alloy and ordinary aluminum rod into single aluminum wire.

The machine absorbs the advanced technology of foreign products, adopts in-line sliding adjustable continuous pulling wire, and the drum is immersed in the pulling oil drawn aluminum wire. The main engine gearbox and cable are respectively equipped with a set of lubrication, cooling and circulation systems.

With the function of quick mold change, the number of spare wire drawing dies can be greatly reduced, saving costs.

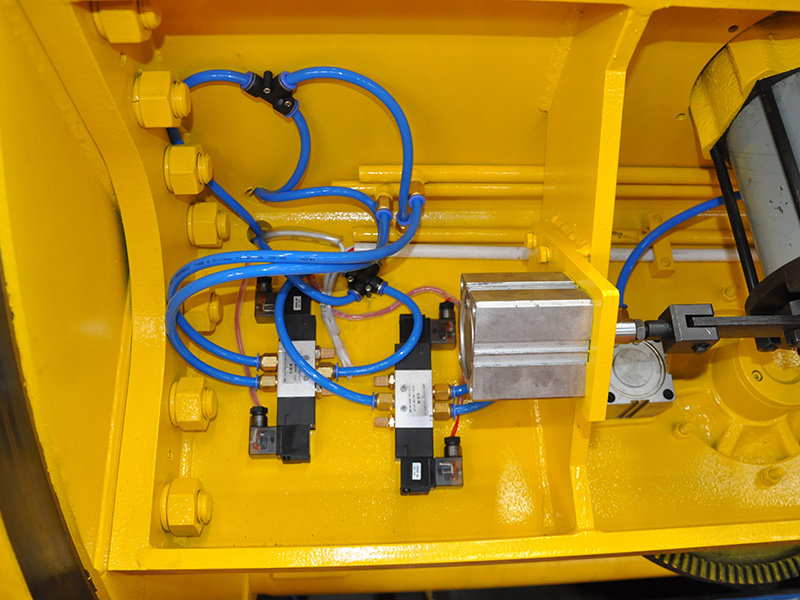

The machine group is completely opto-mechanical and electrically integrated, adopts PLC programming, touch screen full-thread control, and balances mechanical and electrical speed matching, so as to realize fast mold change, full pneumatic non-stop changing of the plate and closing of the line. The production process is displayed on the color touch screen man-machine interface, and the man-machine dialogue is used to query, adjust and control. It has the advantages of convenient operation, high production efficiency and good product quality.

< font face="Song body" > technical parameters

|

model |

drawing passes |

wire diameter (mm). |

straight machine |

outlet speed (m//s). |

|

|

circular line r (mm) / anisotropic cross-sectional area (mm2). |

|||||

|

LFD450/9H |

9 |

9.5 |

2.8~4.5 |

7~16 |

20 |

|

LFD450/11H |

11 |

9.5 |

2.3~4.5 |

7~16 |

22 |

|

LFD450/13H |

13 |

9.5 |

1.8~4.5 |

7~16 |

25 |

3. Unit composition:

Spiral arm double station pay-off frame - wire pulling host - wire oil supply system - lubricating oil circulation system - storage line tension control device - pneumatic single disc take-up device - PLC electrical control system - rolling head mold threading machine.

HOT PRODUCTS

ONLINE MESSAGE