PRODUCTS CENTER

ProduCTS center

It has rich technical experience in the fields of non-ferrous wire, stranded wire, calendering and rolling, and is an innovative and high-tech enterprise in Sichuan Province.

Casting machine

Keywords:

Category:

Product description

XDG2120+255/4+8 copper rod continuous casting and rolling mill

(4+8 rack copper rod continuous casting and rolling line).

technical specification

1. Equipment use and performance characteristics

This production line is mainly used to manufacture φ8mm bright copper rod, and the raw material is electrolytic copper or waste copper.

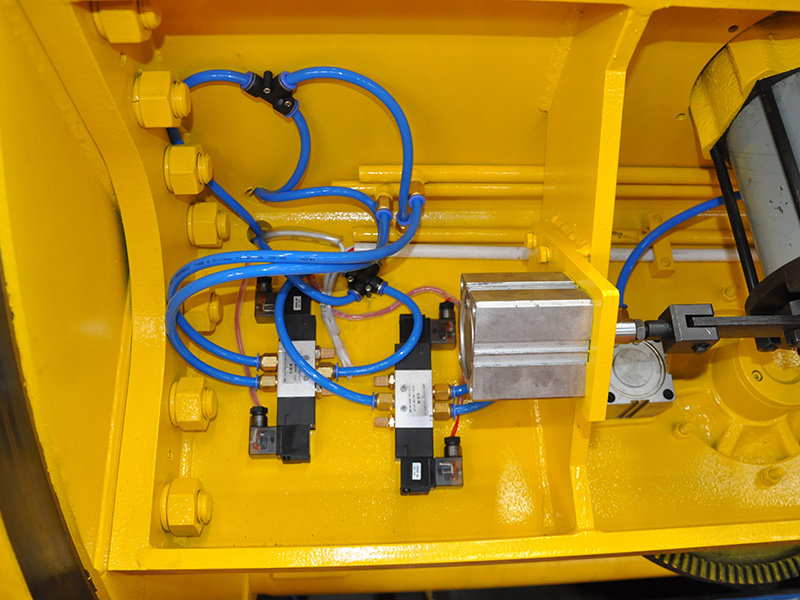

The performance of the production line is characterized by the continuous hot casting and hot rolling process, from raw material melting, ingot casting to rolling finished copper rod in one uninterrupted completion in the production line. The unit is completely opto-mechanical and electrically integrated, and adopts DC speed regulation and AC frequency conversion speed regulation in the production process, full-thread PLC automatic control, color touch screen display and operation, with fault alarm and automatic shutdown functions. High production efficiency, product quality in line with national wire and cable standards.

2. Production process

Feeding (primary and secondary scrap copper), → melting (copper melting open-hearth furnace), → melt protection (launder, pouring pot), → ingots (continuous casting machines, casting cooling systems), → ingot handling devices (front traction feeding→ roller shear→ straightening→ cornering→ wooling), → feeding (active feeding), → rolling rods (continuous rolling mills, gearbox lubrication systems, emulsion cooling lubrication systems) → surface reduction blow-drying (alcohol-water reduction cooling blow-drying system) → copper rod into a circle (plum type rod closing device).

3. Main technical parameters

1. Equipment use and performance characteristics

This production line is mainly used to manufacture φ8mm bright copper rod, and the raw material is electrolytic copper or waste copper.

The performance of the production line is characterized by the continuous hot casting and hot rolling process, from raw material melting, ingot casting to rolling finished copper rod in one uninterrupted completion in the production line. The unit is completely opto-mechanical and electrically integrated, and adopts DC speed regulation and AC frequency conversion speed regulation in the production process, full-thread PLC automatic control, color touch screen display and operation, with fault alarm and automatic shutdown functions. High production efficiency, product quality in line with national wire and cable standards.

2. Production process

Feeding (primary and secondary scrap copper), → melting (copper melting open-hearth furnace), → melt protection (launder, pouring pot), → ingots (continuous casting machines, casting cooling systems), → ingot handling devices (front traction feeding→ roller shear→ straightening→ cornering→ wooling), → feeding (active feeding), → rolling rods (continuous rolling mills, gearbox lubrication systems, emulsion cooling lubrication systems) → surface reduction blow-drying (alcohol-water reduction cooling blow-drying system) → copper rod into a circle (plum type rod closing device).

3. Main technical parameters

1. Equipment use and performance characteristics

This production line is mainly used to manufacture φ8mm bright copper rod, and the raw material is electrolytic copper or waste copper.

The performance of the production line is characterized by the continuous hot casting and hot rolling process, from raw material melting, ingot casting to rolling finished copper rod in one uninterrupted completion in the production line. The unit is completely opto-mechanical and electrically integrated, and adopts DC speed regulation and AC frequency conversion speed regulation in the production process, full-thread PLC automatic control, color touch screen display and operation, with fault alarm and automatic shutdown functions. High production efficiency, product quality in line with national wire and cable standards.

2. Production process

Feeding (primary and secondary scrap copper), → melting (copper melting open-hearth furnace), → melt protection (launder, pouring pot), → ingots (continuous casting machines, casting cooling systems), → ingot handling devices (front traction feeding→ roller shear→ straightening→ cornering→ wooling), → feeding (active feeding), → rolling rods (continuous rolling mills, gearbox lubrication systems, emulsion cooling lubrication systems) → surface reduction blow-drying (alcohol-water reduction cooling blow-drying system) → copper rod into a circle (plum type rod closing device).

3. Main technical parameters

|

1 |

crystal wheel diameter |

φ2120 mm |

9 |

in a circled pattern |

plum shape |

|

2 |

ingot cross-sectional area |

2320 mm2 |

10 |

circle diameter |

φ1800 mm |

|

3 |

rolled form |

2 rolls + 3 rolls |

11 |

the height of the circle box |

1500 mm |

|

4 |

rolling passes |

12(4+8) |

12 |

bundle weight |

3-5 T |

|

5 |

the nominal diameter of the roll |

φ255 mm |

13 |

main motor power |

440kW |

|

6 |

produces copper rod diameters |

φ8.0 mm |

14 |

total installed capacity |

1000KVA |

|

7 |

final rolling speed |

9.8 m/s |

15 |

the weight of the main device |

70t (without furnace). |

|

8 |

production capacity |

13.5-17 T/h |

16 |

device form factor |

40×7.8×5.7m (excluding furnaces). |

HOT PRODUCTS

ONLINE MESSAGE